BMW, a global leader in automotive design and engineering, sought to reflect its brand identity of precision, innovation, and luxury in its new flagship showroom in Abu Dhabi. As part of the showroom’s architectural and interior design, the entrance needed to be an iconic statement that aligned with BMW’s reputation for engineering excellence. To achieve this, a bespoke set of turbine-style push and pull handles was commissioned for the entrance doors.

The BMW showroom management and architects envisioned a door handle design that:

- Reflected BMW’s high-performance, modern, and luxurious brand identity.

- Incorporated a turbine-inspired aesthetic to represent speed, innovation, and the precision engineering of BMW engines.

- Was functional, durable, and capable of withstanding high-traffic use.

- Matched the sophisticated and cutting-edge architectural style of the showroom.

- Provided a unique customer experience from the moment visitors approached the entrance.

The design team collaborated with architects and BMW representatives to translate the brand’s core values into a functional, yet artistic form. The turbine style was selected to draw inspiration from BMW’s engineering heritage, particularly referencing the precision and fluidity of the turbine blades found in engines.

The design process involved:

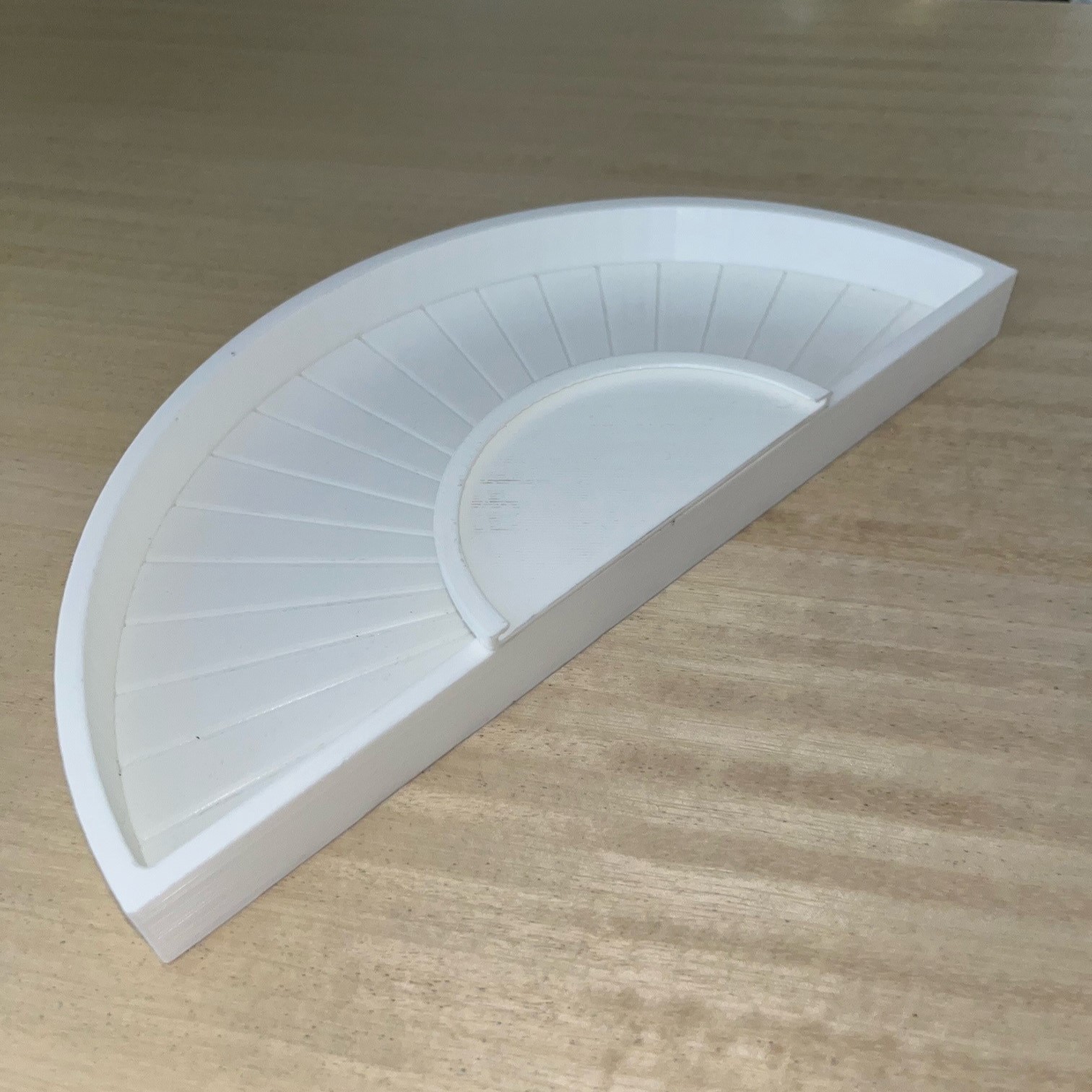

- Sketching Initial Concepts: The team started by drafting hand-drawn sketches of the handle, focusing on dynamic lines, symmetry, and an elegant curvature that would echo the movement of turbine blades.

- Digital Modeling: After refining the sketches, the design team created 3D CAD models to visualize the handles in the context of the showroom doors. The models helped assess proportions, ergonomics, and visual impact.

- Material Selection: High-quality materials such as stainless steel and brushed aluminum were chosen to ensure durability, resistance to corrosion in the desert climate of Abu Dhabi, and to provide a sleek, high-end finish. The materials were also chosen for their ability to reflect light, creating a visual focal point at the entrance.

The next phase involved translating the design into a functional product:

- Engineering Feasibility: The engineering team assessed the structural requirements to ensure the handles could bear the weight of heavy glass doors while maintaining ease of use. Load-bearing simulations were conducted to confirm the strength of the attachment points and overall durability.

- Prototyping: Using CNC (Computer Numerical Control) machining, a prototype of the handle was created. The prototype was tested for aesthetics, ergonomics, and strength. Feedback from both the BMW team and architects led to slight refinements in the handle’s curvature and finish.

Once the final design was approved, full-scale manufacturing began:

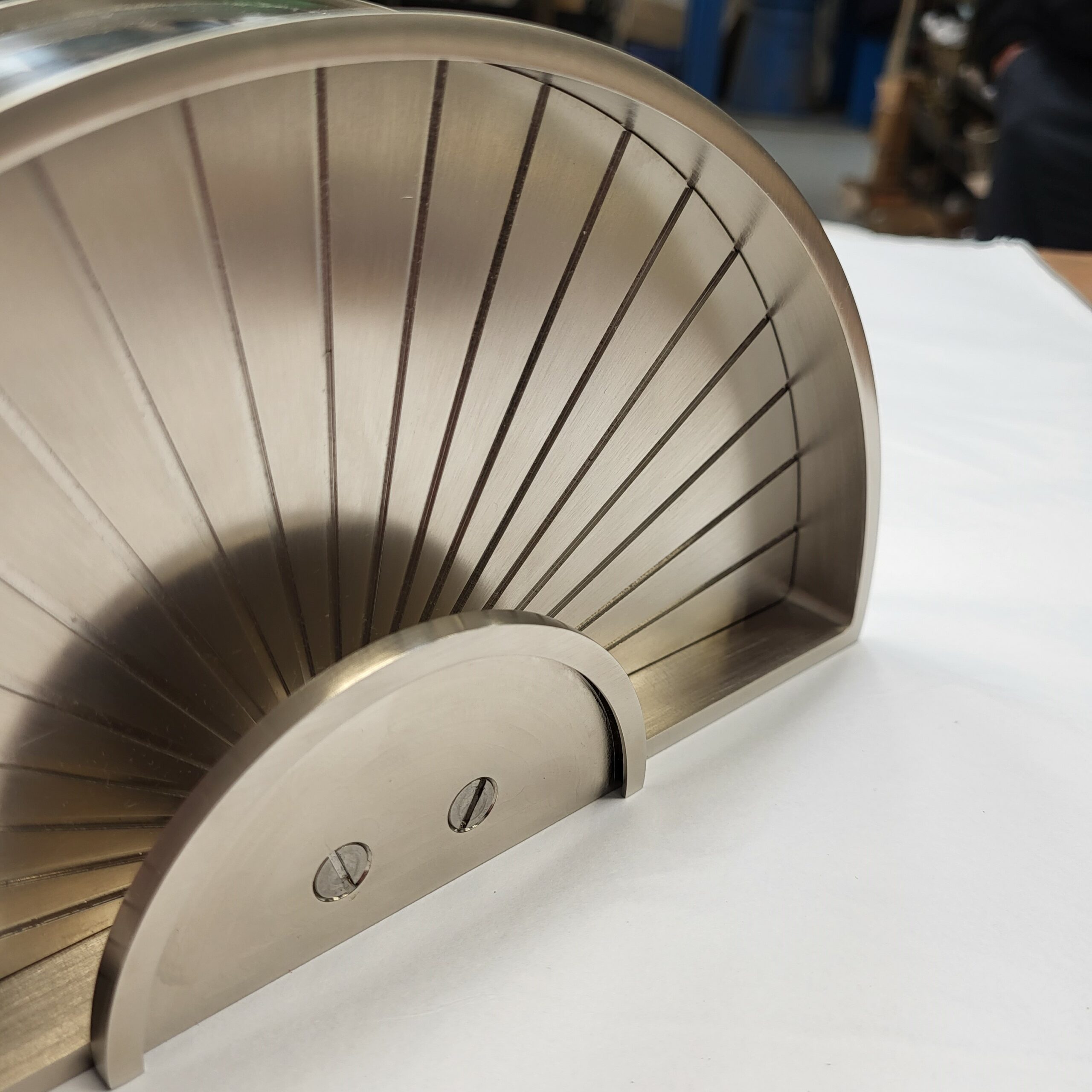

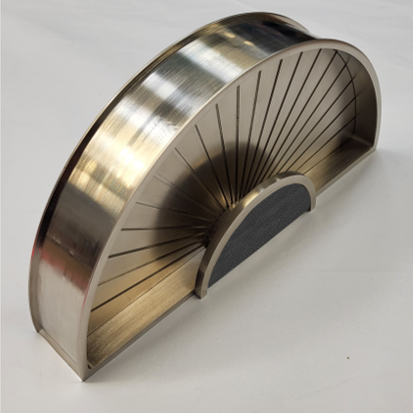

- Material Cutting and Shaping: Stainless steel and aluminum sheets were cut with laser precision to form the basic shape of the turbine blades. CNC milling machines were used to ensure consistency and accuracy in the shape of the handle components.

- Polishing and Finishing: Each handle underwent meticulous polishing to achieve a brushed finish, which not only enhanced the visual appeal but also provided a tactile feel that resonated with BMW’s premium branding.

- Assembly: The individual components of the turbine-style handles were assembled using high-strength adhesives and fasteners. Special attention was given to alignment and ensuring that the final product was free of visible seams or inconsistencies.

Installation of the handles was carried out on-site at the BMW showroom in Abu Dhabi. Given the unique design, the team faced challenges in aligning the handles with the glass doors to ensure both functionality and aesthetic harmony. The handles were attached using concealed fasteners, which enhanced the clean, minimalist look while providing the necessary structural support.

The design and manufacture of the bespoke turbine-style push and pull handles for the BMW flagship showroom in Abu Dhabi showcased the successful collaboration between industrial design, engineering, and brand identity. By focusing on precision, material quality, and innovative design, the handles not only served as functional components but also as an embodiment of BMW’s core values of performance, luxury, and engineering excellence.

The project serves as an example of how thoughtful design and meticulous engineering can create a functional art piece that enhances both customer experience and brand image.